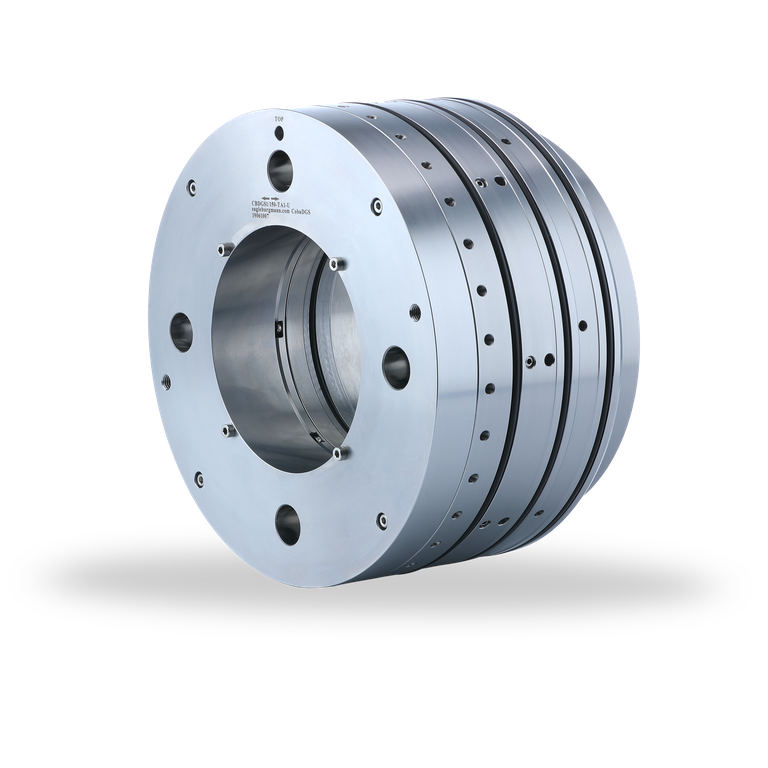

RoTechSeal

RoTechSeal

RoTechSeal tandem seal

| A | Primary seal gas supply |

| B | Primary vent |

| C | Secondary seal gas supply |

| S | Secondary vent |

| D | Separation gas supply |

| Pos. | Benennung |

| 1 | Seal face, stationary |

| Feature option: primary seal face with DiamondFace-coating | |

| 2 | Seat, rotating |

| Feature option: primary seat with DiamondFace-coating | |

| 3 | Thrust ring |

| 4 | Shaft sleeve |

| 5 | Adapter sleeve |

| 6 | Housing (size matched to installation space) |

| 7 | Separation seal (CobaSeal) |

| 8 | Labyrinth |

| 9 | Feature option: "smart labyrinth" |

| 10 | Feature option: "soft torque" |

| 11 | Feature option: debris resistant dynamic sealing element |

RoTechSeal

Features

The efficient sealing solution with advanced robustness against seal gas supply contamination(particles/liquids)

- Gas-lubricated

- Uni- or bi-directional

- Ready-to-fit cartridge unit

- Available for all seal arrangements: single, double, tandem

- Based on proven DGS or PDGS design

- Separation seals as labyrinths, carbon rings or CobaSeal optional

Advantages

The reliable DGS or PDGS is made even more robust by design measures and features:

- "Smart Labyrinth"

- DiamondFace-coating

- Self-cleaning 3D gas grooves

- Soft torque transmission

- Debris resistant dynamic sealing element

- Leakage optimization

Materials

Seal face: Silicon carbide with DLC- or DiamondFace-coating

Seat: Silicon carbide with DLC- or DiamondFace-coating

Secondary seals: PTFE or FKM

Metal parts: 1.4006, 1.4313-QT650, 1.4418, 1.4542, Inconel® or other stainless steels

Other materials on request

Standards and approvals

- NACE

- API 617

- API 692

Recommended applications

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Applications with upstream gas treatment (glycol)

- Hydrocarbon gas

- Ammonia

- Nitrogen

- All types of compressors

Notes

One of the biggest challenges in operating centrifugal compressors with dry gas seals is seal gas supply contamination. Liquids or particles in the supply gas are the main causes of shortened seal life. With special features, the RoTechSeal increases the lifetime of a normal seal in a wet and dirty environment. The robust seal features will be defined case-by-case based on the operating conditions and failure analysis.

Dimensions on request.

Similar products

CobaDGS - Zero Emission Solution

The sealing solution for reduction of methane-/ process gas emissions

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Available for following seal arrangements: single and tandem

- Co-axial primary seal

- Separation seals as CobaSeal, carbon rings or labyrinths optional

RigiSeal

Developed in coorperation with MAN Energy Solutions, based on the extremely robust EagleBurgmann RoTechSeal

- Modular design

- As upgrade of MAN centrifugal compressors or for new projects

- Availabe as single, double, or tandem seal

- Gas-lubricated

- Uni- or bi-directional

- Ready-to-install unit

- Optionally with separation seal such as labyrinths, carbon rings or EagleBurgmann CobaSeal