EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

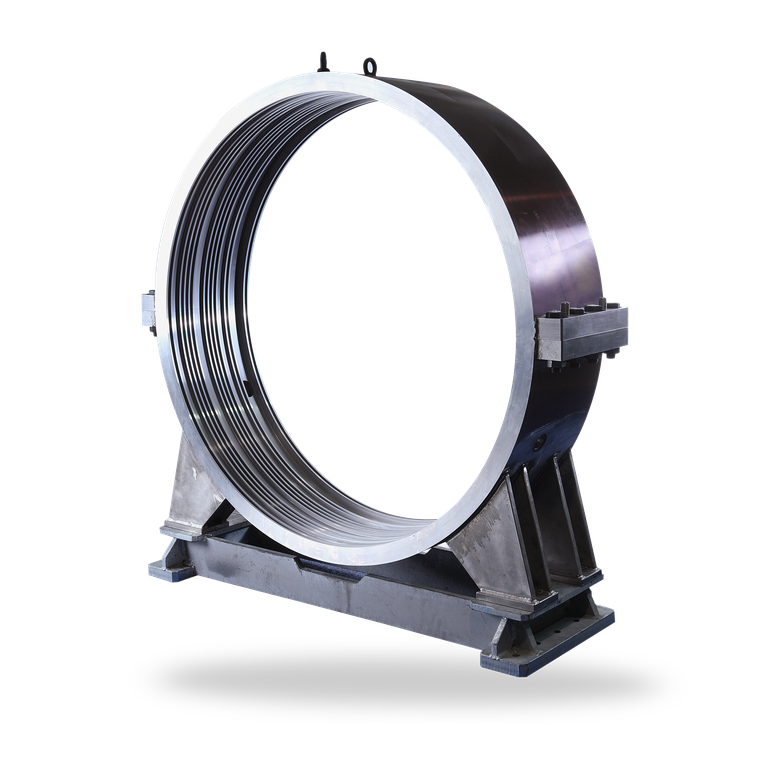

Espey WDK-BHS

| Item | Description |

| 1 | Flat seal |

| 2 | Housing, 2-piece |

| 3 | Seal ring |

| 4 | Tension spring |

| 5 | Detent |

| 6 | Spring |

Espey WDK-BHS

Features

- Multi-part seal rings, radially cut

- Split housing design

- Short axial installation length (max. 36 mm)

- Very small operation gap

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Seals on both sides of the shaft

- Resistant to sea water

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power

Advantages

- Easy installation by split housing design (shaft removal not required)

- Long-term operation time

- Maintainability

- Segmented seal rings for easy replacement

Operating range

d = 40 ... 800 mm (1.57" … 31.5")

Operating pressure:

p = vacuum ... 3 bar (43 PSI) abs.

Operating temperature:

t = max. 225 °C (437 °F)

Sliding velocity: vg = max. 40 m/s (131 ft/s)

Radial play: ±5.0 mm (±0.2") (depending on shaft diameter)

Axial movement: theoretically unlimited

Angular deviation: ±2° (central installation, depending on shaft diameter)

Materials

Housing: 1.4571, others

Tension spring / detent: 1.4571

Standards and approvals

- ISO 9001

- American Bureau of Shipping (ABS),

- Bureau Veritas, Lloyd's Register EMEA,

- Det Norske Veritas, Russian Maritime Register of Shipping,

- Germanischer Lloyd and others

Recommended applications

- Shipbuilding

- CO2 transportation and storage

- Sea water, water

- Drive shafts in ships, bulkheads

Similar products

Espey Magna500+ the large seal for diameters from 500 mm

- Split housing design

- Segmented and self-adjusting seal rings

- Virtually maintenance- and wearfree

- Dry-running

- Suitable for horizontal and vertical use

Espey WKA1200

- Available as modular Cartridge-Seal

- Flexible layout due to operating parameters

- Weight optimized

- Minimal vibrating mass

- High operational realiability

Inquire about individual solutions

We develop and produce customer-specific special and individual solutions for every application.

The Eagleburgmann Group

Sealing technology for plants and machines

EagleBurgmann is one of the worldwide leading providers of industrial sealing technology. Mechanical seals, seal supply systems, magnetic couplings, carbon floating ring seals, expansion joints, gaskets and packings as well as comprehensive services are used wherever reliability and safety are needed.

Mechanical seals and more

Sealing technology by EagleBurgmann is used worldwide in oil and gas industries, refineries, the petrochemical, chemical, and pharmaceutical industries, food processing, energy, water, mining, paper, aerospace, and other industries. Close to 5,800 employees provide their ideas, solutions, and commitment so that customers can rely on our sealing technology.

What makes us stand out is our excellent quality, great innovative capacity, and an extensive product portfolio for nearly all industrial processes and fields of application. Our product portfolio includes everything from mechanical seals and seal supply systems to magnetic couplings, carbon floating ring seals, expansion joints, and gaskets and packings as well as comprehensive services. Since we are part of the German Freudenberg and Japanese EKK group, we have all the necessary resources for a firmly based reliable partnership.