Situation

Bearing oil contaminates the compressor seals and causes multiple failures.

DGS compressor seal and the world's largest operating CobaSeal

Bearing oil contaminates the compressor seals and causes multiple failures.

Compressors may not be shut down in winter.

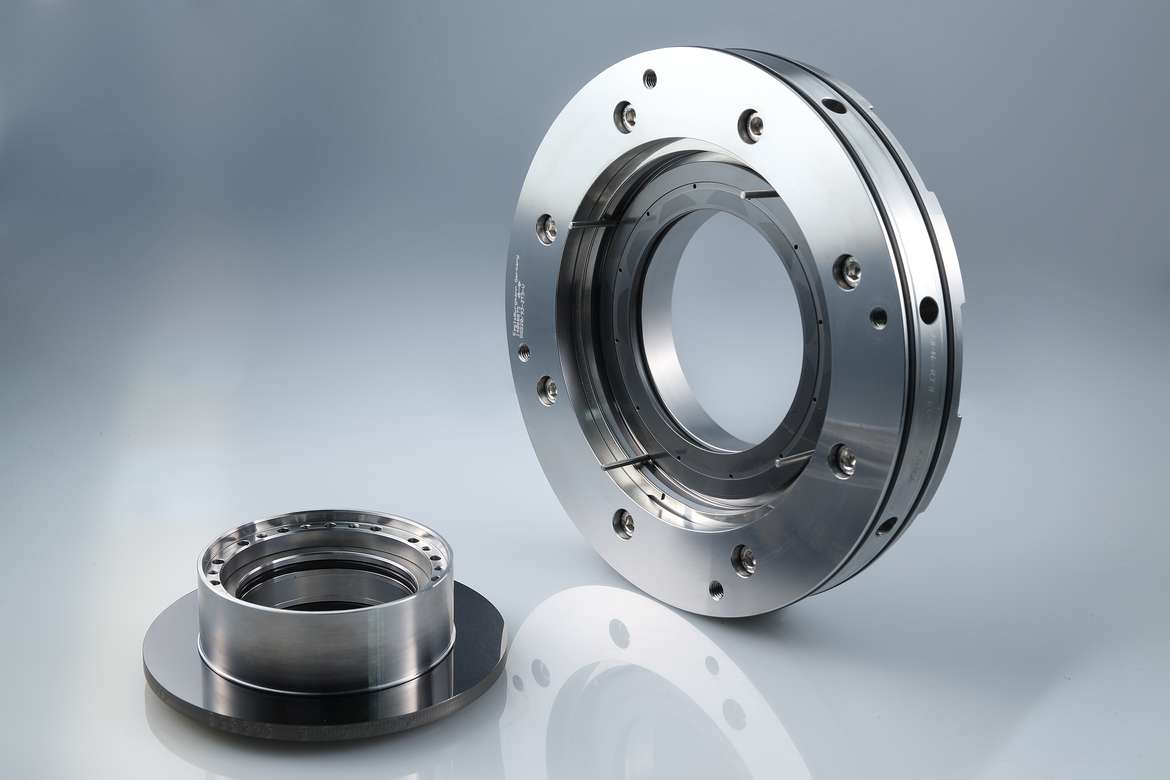

Mechanical seal DGS and separation seal CobaSeal by EagleBurgmann

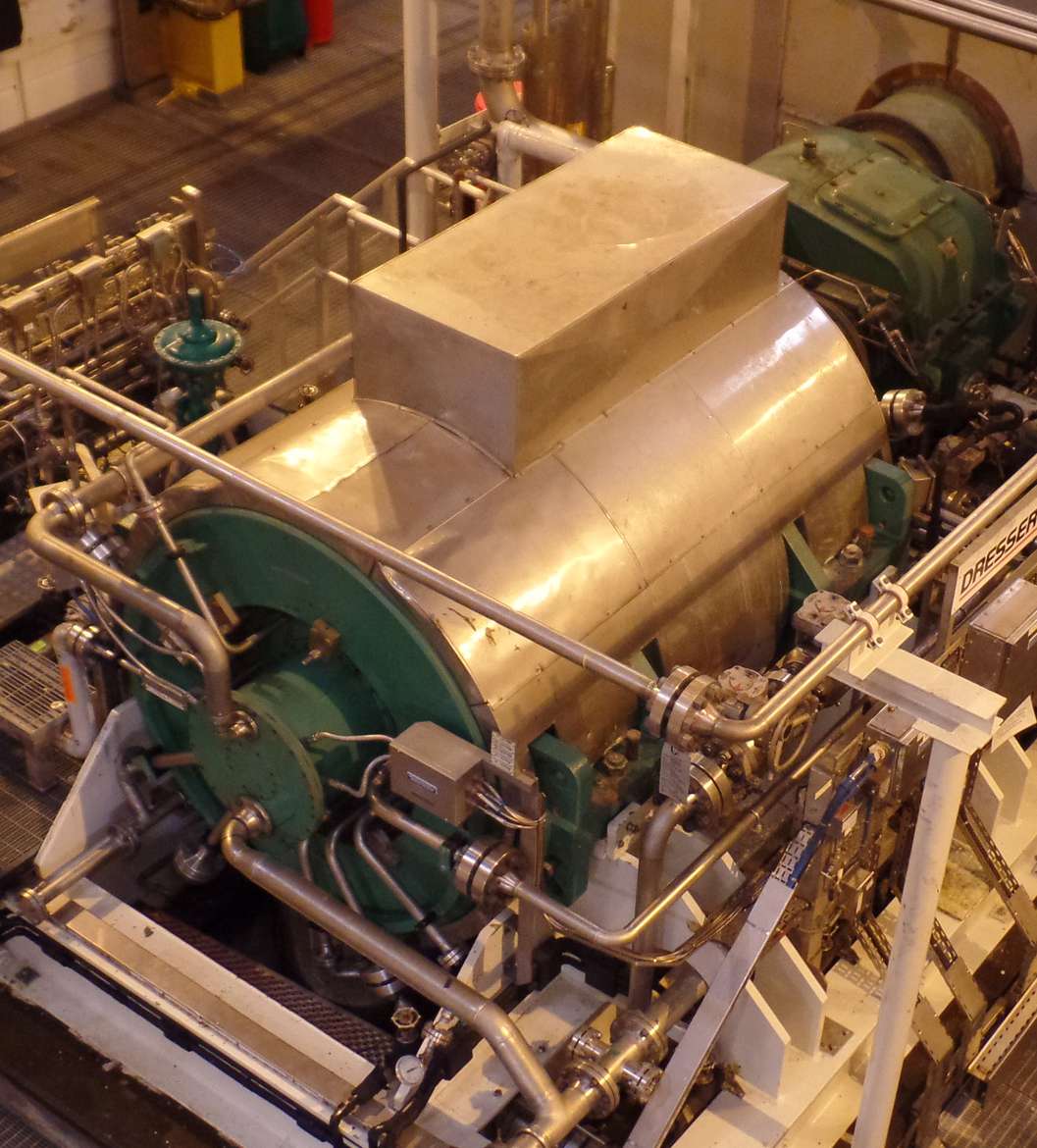

The Norwegian oil and gas group Equinor ASA operates the large Kollsnes gas processing plant west of the city of Bergen. Natural gas from the Troll, Kvitebjørn, Visund and Fram fields is separated here into dry methane and NGL (Natural Gas Liquids). The plant currently has a daily processing capacity of 143 million cubic meters of methane and 69,000 barrels of NGL. For such volumes, it is clear that the compressors must operate reliably at all times.

The operator faced a corresponding amount of work when, after commissioning the natural gas compressors, the separation seals were not performing properly. Bearing oil reached the seal chamber and contaminated the dry gas seals, which resulted in multiple seal failures.

This situation forced the operator to carry out an extensive maintenance program for the seals and to replace them every two years as a preventive measure, as the compressors could not be shut down from October to April. This entailed high costs while there was still a certain potential for errors. Equinor decided to have the sealing solution completely overhauled and commissioned EagleBurgmann to develop a reliable sealing concept.

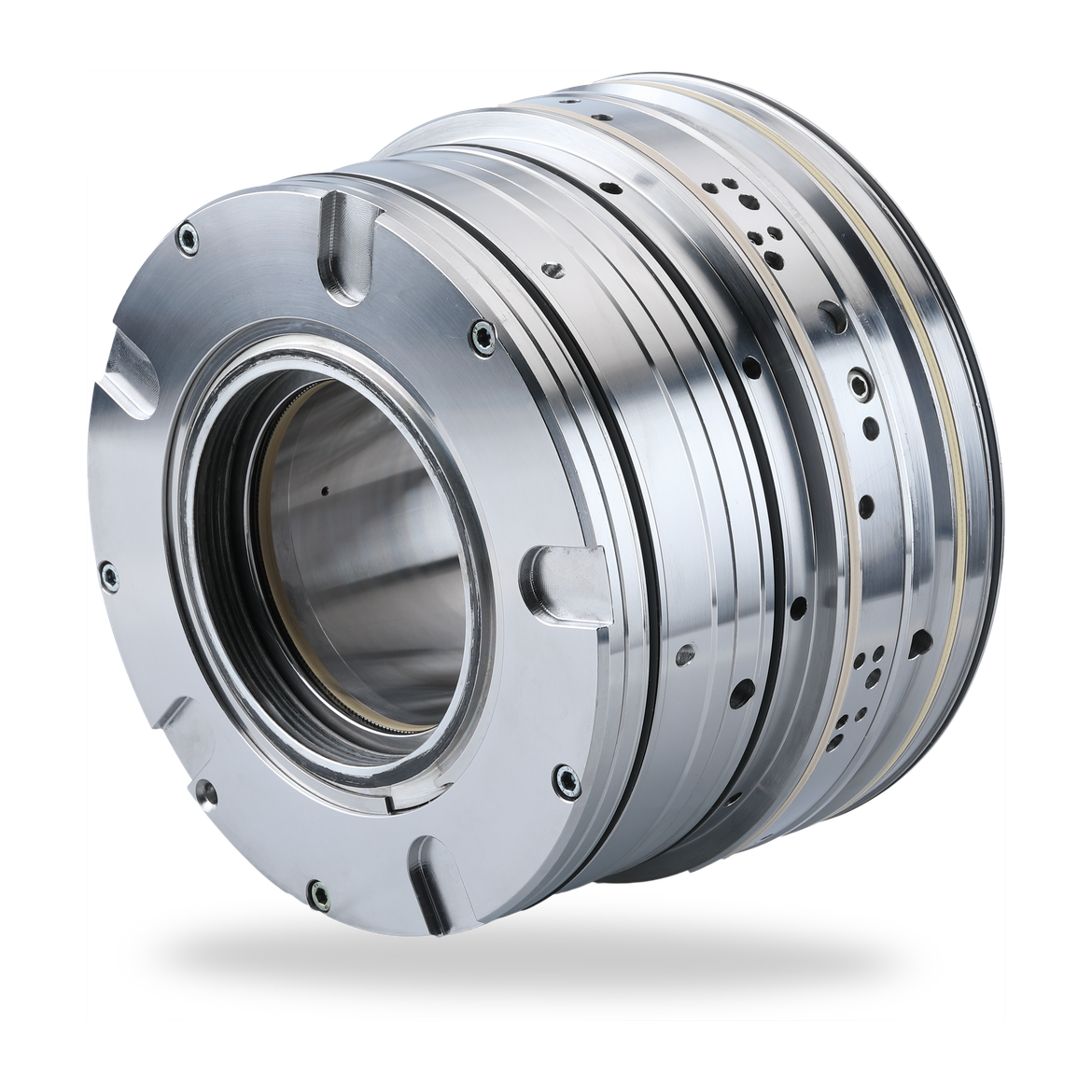

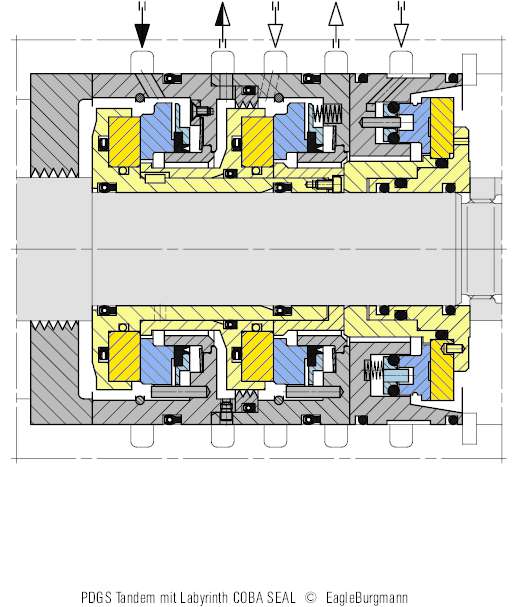

After detailed investigations, EagleBurgmann retrofitted one of the compressors with a dry gas seal cartridge “DGS” including the "CobaSeal" as the separation seal. One of the key features of this innovative separation seal is very low leakage. The leakage rates are up to 95 % lower than those of conventional separation seals such as labyrinths or seals with carbon rings. Apart from low leakage, the very small coaxial sealing gap also ensures complete oil tightness, even if the nitrogen barrier fails briefly or shows irregularities. Not only is retrofitting worthwhile for reasons of reliability, but also to permanently reduce the need for nitrogen as a separation gas and thus operating costs.

The CobaSeal had already demonstrated its robustness and reliability in many applications. However, this seal with a diameter of 200 mm (7.87") in a real field application was something new at that time. Success was immediately noticeable: the compressor with the world's largest operating CobaSeal from EagleBurgmann so far, has been running reliably ever since.

This is shown time and again: The customer empties the chamber between the separation seal and the dry gas seal in all six export compressors on a weekly basis. The CobaSeal alone has so far perfectly sealed the bearing chamber of the shaft. Compared to the other separation seals, nitrogen consumption is the most stable and about 40 % lower (0.8 to 1.0 Sm3/h on the drive end and 1.2 to 1.4 Sm3/h on the non-drive end). Consumption is no longer varying as it did with the former separation seal, which is another clear indicator that barrier oil is no longer reaching the DGS.

Equinor can also rely on the fact that the CobaSeal will have a much longer service life than its predecessor seal: Its unique coaxial design ensures that the sealing rings are non-contacting and therefore non-wearing in all operating conditions.

The low process gas leakage rates of the DGS dry gas seal are ensured by bi-directional 3D gas grooves in conjunction with silicon carbide sealing faces and an extremely small sealing gap. The bi-directional design also increases the robustness and safety of the seal as it can rotate in both directions without damage. This feature prevents seal damage when compressors unexpectedly reverse rotation.

The customer confirmed to EagleBurgmann that the new DGS has about 70 % less leakage than the seals in the other compressors. This is reflected economically with considerable savings: The operating costs for this one compressor with the DGS are thus reduced by about 25,000 euros per year. 70 % less methane leakage also means less CO2 emissions due to flaring off the leakage and consequently less CO2 tax burden for the operator.

Compressor operating conditions

Case Study on DGS compressor seal and the world's largest operating CobaSeal (seperation seal).

EagleBurgmann CobaSeal - the biggest co-axial separation seal ever built. Watch the video now!

Dry gas seal solutions - A guide to a safer and more reliable operation of compressors. 10 cases with indications, causes and remedies.

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.